Contacts & services

Catalog

Automatics and control

Cables and wires

Installation

Show All

Alarm and security systems

Cable bearing systems

Cable connectors

E-mobility

Fixings

Installation pipes

Tools, measuring instruments and protection

Cable inlet

Data and telecommunication

Electric box (breaker panel)

Industrial connections and blocks

Installation boxes

Lighting protection

Mounting materials

Power supply elements and devices, reactive power compensation

LED lighting

Lamps

Lighting accessories

Luminaires

Show All

Emergency luminaires and accessories

Explosion proof luminaires

Flashlights, batteries and acessories

Industrial lights

LED Panels and accessories

LED strips, modules, profiles and accessories

Linear and modular luminaires

Street and park luminaires

Track lights and accessories

Built-in mounting lamps

Ceiling mounting lamps

Festive lightings

Floor lamps

In-ground luminaires

Machine and work bench luminaire

Pendant lights

Recessed lights

Surface mounting lamps

Table lamps

Wall mounting lamps

Renewable energy

Switches and sockets

Ventilators, pumps and gate operators

Show All

Accessories (ventilators, pumps and gate operators)

Air freshener

Air inlet/extraction units

Air treatment

Boilers and heaters

Cooling systems

Distributors

Fans

Filters/separators

Fittings for doors and gates

Heating appliances

Industrial fans

Trace heating cables and electric surface heating

Ventilation and air conditioning systems

Sign in

Don’t have account?

Create account

Register to unlock your exclusive B2B prices and start shopping. Sign up now!

- Home /

- Automatics and control /

- ABSOLUTE ENCODER MULTITURN 6FX2001-5VD25 36 BIT WITH DRIVE-CLIQ; HOLLOW SHAFT 10MM Optoelectronic mounted rotary encoders

- Home /

- Installation /

- Tools, measuring instruments and protection /

- Measuring instruments /

- ABSOLUTE ENCODER MULTITURN 6FX2001-5VD25 36 BIT WITH DRIVE-CLIQ; HOLLOW SHAFT 10MM Optoelectronic mounted rotary encoders

- Home /

- Siemens /

- ABSOLUTE ENCODER MULTITURN 6FX2001-5VD25 36 BIT WITH DRIVE-CLIQ; HOLLOW SHAFT 10MM Optoelectronic mounted rotary encoders

- Home /

- Siemens +

- Automatics and control /

- ABSOLUTE ENCODER MULTITURN 6FX2001-5VD25 36 BIT WITH DRIVE-CLIQ; HOLLOW SHAFT 10MM Optoelectronic mounted rotary encoders

- Home /

- Siemens +

- Installation /

- Siemens Installation +

- Tools, measuring instruments and protection /

- Siemens Tools, measuring instruments and protection +

- Measuring instruments /

- ABSOLUTE ENCODER MULTITURN 6FX2001-5VD25 36 BIT WITH DRIVE-CLIQ; HOLLOW SHAFT 10MM Optoelectronic mounted rotary encoders

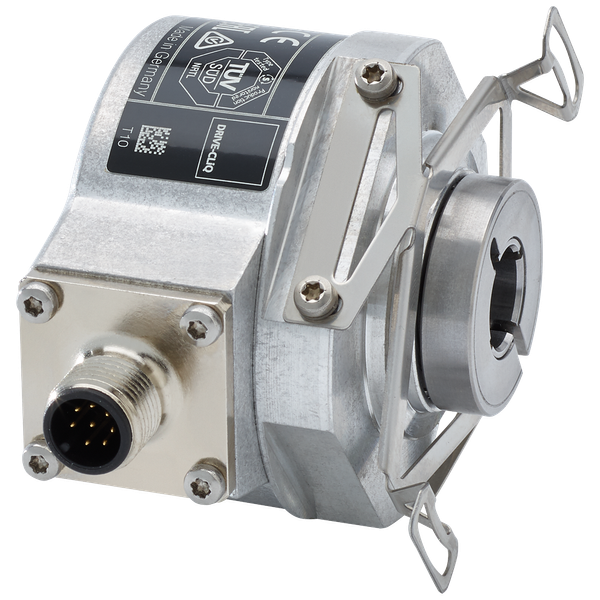

ABSOLUTE ENCODER MULTITURN 6FX2001-5VD25 36 BIT WITH DRIVE-CLIQ; HOLLOW SHAFT 10MM Optoelectronic mounted rotary encoders

In stock: No

Vendor stock: No

Minimal order quantity: 1

Price (excl. VAT):

934,78 €

EAN: 0804766369926

MPN: 6FX2001-5VD25-1AA0

Package: 1

Estimate delivery time at our warehouse (approx.):

4-6 weeks

Technical Information

| Item condition | New |

| Manufacture name | ABSOLUTE ENCODER MULTITURN 6FX2001-5VD25 36 BIT WITH DRIVE-CLIQ; HOLLOW SHAFT 10MM Optoelectronic mounted rotary encoders |

| Brand | Siemens |

| Categories |

Automatics and control

Measuring instruments |

| Country of origin | DE |

| Harmonized System Code | 9031 4990 00 |

| Contact less rotational speed measuring (optic) | - |

| Mechanic rotational speed measuring | - |

| Measurement surface speed | - |

Packing details

| Packing level 1 | 0804766369926 |

Description

ABSOLUTE ENCODER MULTITURN 6FX2001-5VD25 36 BIT WITH DRIVE-CLIQ; HOLLOW SHAFT 10MM Optoelectronic mounted rotary encoders measuring systems motion control encoders absolute encoders with DRIVE-CLiQ for SINUMERIK, SIMOTION, SIMATIC, SINAMICS. Motion control encoders are optoelectronic mounted encoders that detect the traversing distances, angles of rotation, speeds or the positions of machine axes. Motion control encoders are direct measuring systems that are mounted onto shafts, axes or motors. They can be used in conjunction with numerical and programmable logic control systems, drives as well as position displays. Another advantage is that motion control encoders are system-tested, certified components that have been optimally harmonized for use with the following systems: SINUMERIK CNC systems, SIMOTION motion control systems, SIMATIC programmable logic control systems and SINAMICS drive systems. Singleturn absolute encoders output an absolute angular position between 0° and 360°. Multiturn encoders also sense the number of revolutions. They operate with the same scanning principle as incremental encoders, but have a higher number of tracks. The code used is a one-step code (gray code), which means that no scanning errors can occur. After switching on the machine, the position value is transferred immediately to the control system, travel to a reference point is not necessary. Absolute encoders also support the DRIVE-CLIQ interface. A very high data transfer rate is one of the benefits of this type of interface. Advantages are also available for time-critical applications, and electronic type plates facilitate simple and fast auto configuration. It should also be mentioned that simple and fast diagnostics are possible using just one tool and that there is one interface for connecting drives as well as indirect and direct measurement systems to the CNC system. SMC / SME sensor modules are not required when establishing a connection to SINAMICS. Absolute encoders with DRIVE-CLiQ and an operating voltage of 24 V are available with a radial connection in the synchro flange design with solid shaft, clamping flange with solid shaft and torque arm with hollow shaft, and either 10 mm or 12 mm diameter. All absolute encoders are available in singleturn and multiturn versions. For singleturn encoders, the resolution is 24 bit and for multiturn encoders, 36 bit. SINUMERIK, SIMOTION, SIMATIC, SINAMICS - perfectly harmonized drive components.